Process Automation

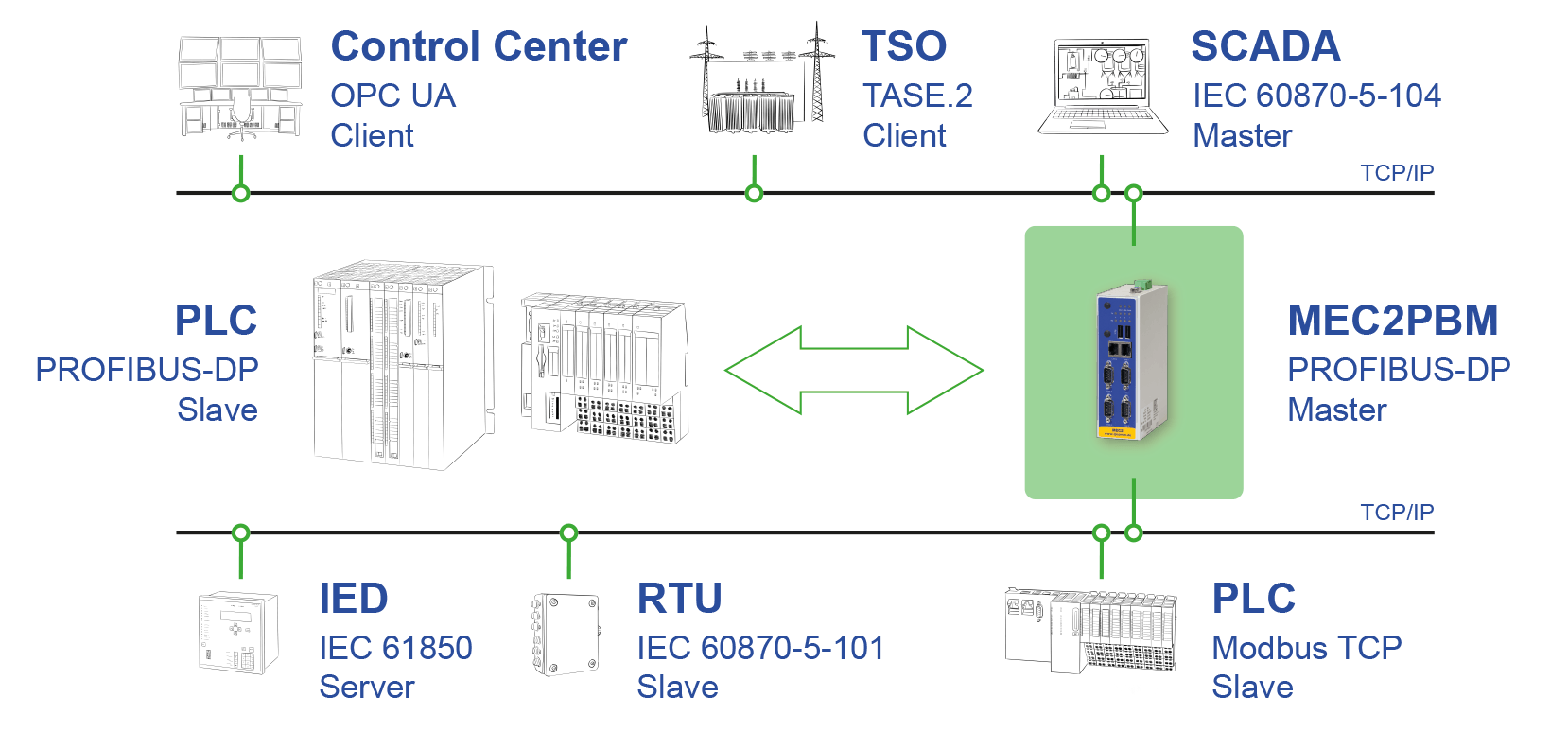

Process automation in the industrial sector (such as mechanical engineering and plant construction) primarily relies on the use of field buses. Our protocol converter enables data to be transmitted from the field bus (controller, sensors, actuators ) to the superior control center.

This specific application can be implemented with our ipConvLite protocol converter, which is capable of using the Profibus DP protocol to communicate with the Profibus.

Selected protocols are provided for communication with other devices (master or slave).

The IPCOMM proprietary Profibus DPV0 application layer enables the transmission of data such as quality descriptors and time stamps. Using the application layer requires however that the Profibus distant terminal is also capable of sending and receiving information over this protocol.

The Midrange Embedded Controller (MEC2 PROFIBUS) with Profibus interface may be used as a suitable hardware platform.

Reference project: IBIRITE

The ipConvLite or ipConv protocol converters allow the connecting of MODBUS field devices.

Selected protocols are provided for ipConvLite to enable communication with the control center.

Reference projects: ISKI, PEMEX, Madero

Other field buses such as Profibus DPV1, 3964R, Sinec-H1 can be connected using our universally compatible ipConv protocol converter, as long as there are appropriate field bus interfaces for the hardware platforms (SEC3, MEC2, MEC3, IPC191V5 19" 1U or IPC191X1 19" 1U).

Reference projects: Project CFE, Burfell, NPC San Manuel, Labrador, I-SHAPE, FSC HECHI

The ipConvLite and ipConv protocol converters are also capable of linking different field buses, for instance MODBUS and Sinec-H1.

or further information about protocol conversion / fieldbus, please Contact our sales team.

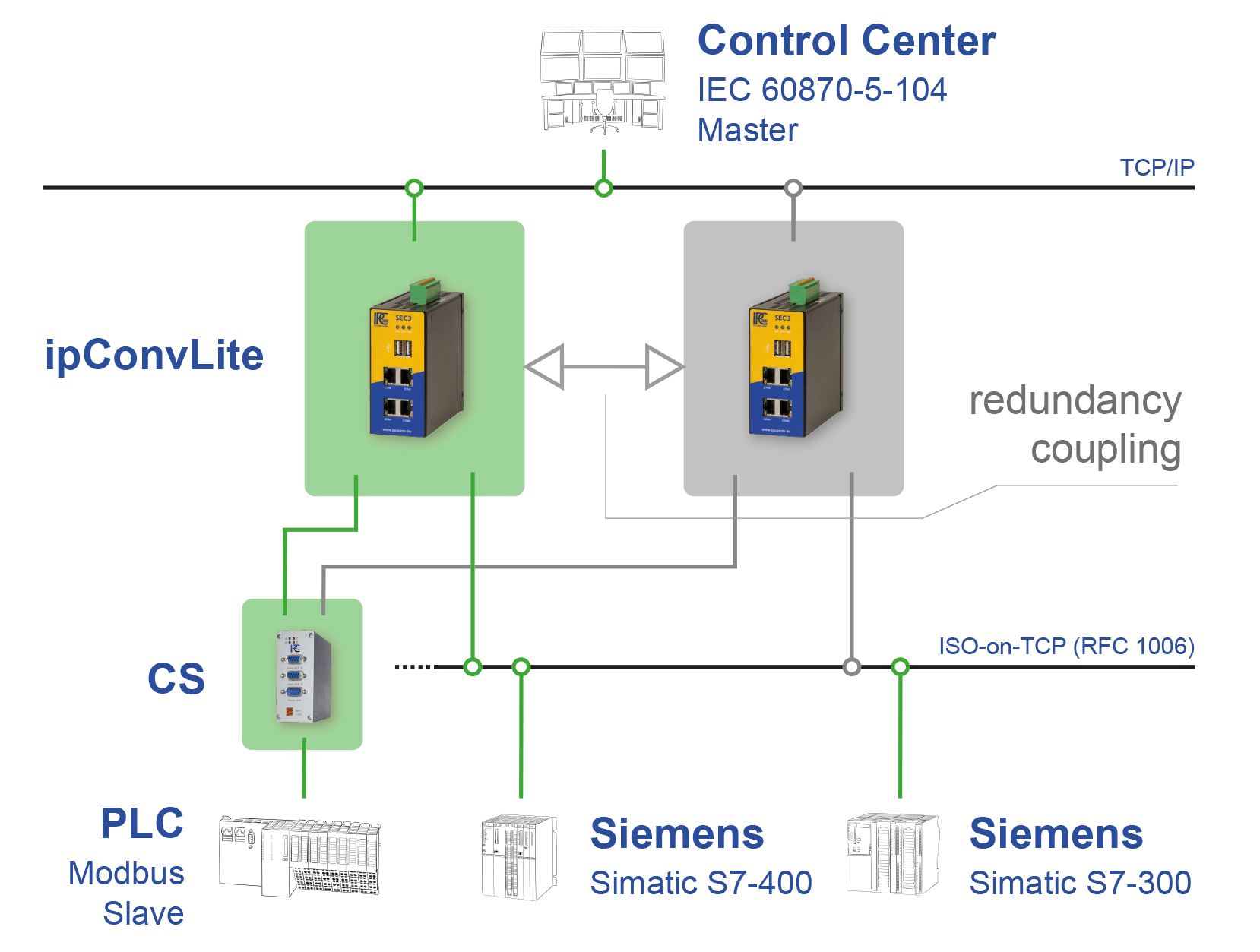

ipConvLite offers a universial solution to connect Siemens Simatic devices of the S7-300/400/1200/1500 family to protocols such as IEC 60870-5-101, IEC 60870-5-103, IEC 60870-5-104, Telegyr 809, OPC UA, OPC Classic. It is not necessary to modify the Simatic's existing programming.

This example shows an ipConvLite gateway upstreaming data to a remote control unit via the IEC 60870-5-101 protocol. Process data is also provided for local monitoring and control via the OPC UA interface.

The following figure shows a redundant configuration for the example scenario.

The redundant coupling can be realized over a serial RS232 line or over Ethernet. The active device is monitored by the passive one. If the active device fails, the previously passive device is activated and assumes its communication.

The superior control center is also redundantly supplied with data via IEC 60870-5-104.

In addition, the communication with a programmable controller involves the Modbus protocol. At this point, data can also be transferred directly between the Modbus controller and the Simatic controller.

The advantages at a glance

- direct access to all data areas of a Simatic S7-300/400/1200/1500 controller via the Simatic Fetch/Write interface or the S7 Protocol (RFC 1006)

- no Simatic programming necessary

- fast integration 'on the fly', no service interruption of existing systems

- simultaneous connection of several controllers

- configurable data areas and access cycles

- object oriented access, data is NOT transferred blockwise, but individual data points

- may be used in combination with all implemented protocol stacks (see also ipConvLite)

- supports nodes, i.e. simultaneous communication with multiple devices using different protocols

- time stamping on change of data (configurable)

- time synching via Network Time Protocol (NTP), communication protocol or external GPS/DCF77 module

- redundant operation possible